Trucking troubles can significantly disrupt operations and even compromise safety on the road. This thorough guide dives deep into common mechanical failures and effective roadside repairs, providing practical solutions to keep your trucks running smoothly and safely. Whether you’re a seasoned trucking professional or a novice in the industry, understanding these critical issues is essential for maximizing efficiency, minimizing downtime, and ensuring a safe operating environment. This article breaks down the most prevalent trucking problems, examining their causes, diagnostic approaches, and effective repair strategies. The structure of this article follows a clear path: first we look at the common problems and their causes, then we’ll cover troubleshooting, and finally, we’ll conclude with practical steps to mitigate these issues in the future. Let’s embark on this journey towards conquering trucking troubles!

Understanding Common Mechanical Failures:

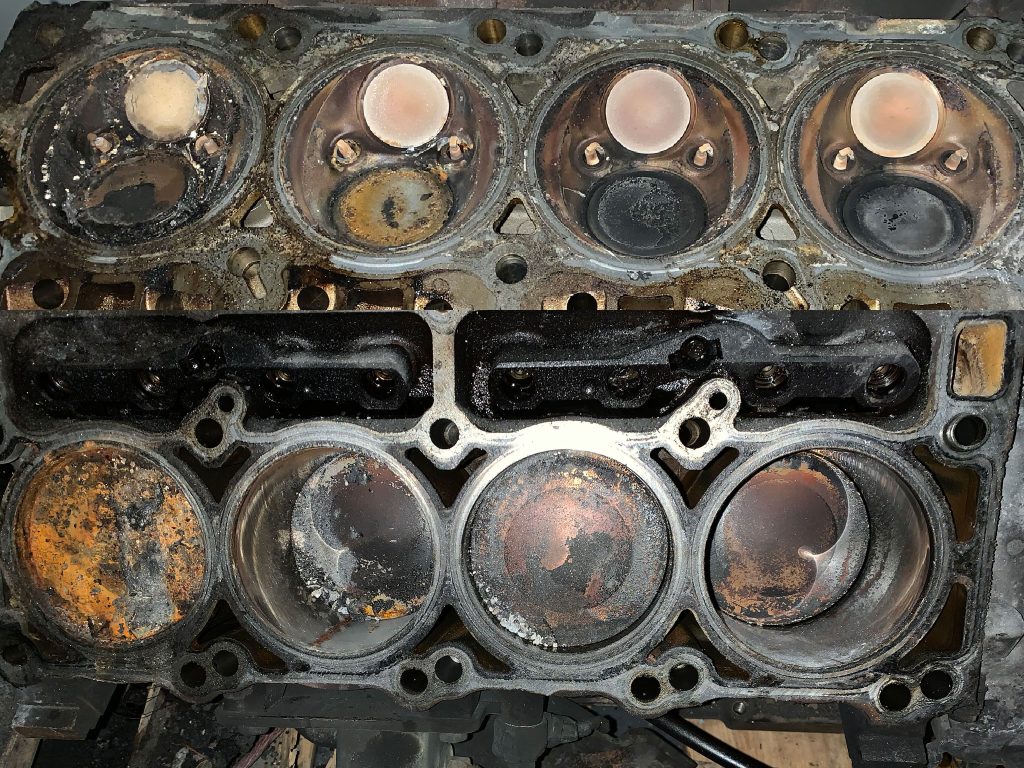

Engine Problems:

Engine failures are one of the most significant trucking troubles, often leading to significant delays and costly repairs. Overheating, oil leaks, and fuel delivery issues are frequent culprits. Early detection is paramount. Regular maintenance, including oil changes, filter replacements, and thorough inspections, can help prevent these problems. Example: A sudden loss of power in the middle of a long haul is a clear sign of a potential engine issue.

Troubleshooting and Diagnostic Tools:

Recognizing Warning Signs:

Detecting potential problems early is crucial in the trucking industry. Drivers should be trained to recognize warning signs, such as unusual noises, vibrations, and changes in performance. For instance, a distinct grinding noise emanating from the engine compartment could signal a bearing failure. These observations are vital initial steps in pinpointing the root of the issue. Advanced diagnostic tools and software can aid in this process.

Employing Modern Diagnostics:

Modern diagnostic tools, such as computerized scanners, offer sophisticated methods for analyzing the truck’s systems. These scanners can pinpoint specific issues like faulty sensors or malfunctioning components. Utilizing these advanced tools expedites the repair process and minimizes downtime. Advanced data examination systems can predict potential failures, allowing for preventative maintenance.

Addressing Roadside Repairs:

Essential Tools and Equipment:

Having the right tools and equipment on hand is critical for effective roadside repairs. Basic tools, such as wrenches, screwdrivers, and pliers, are standard. Additional specialized tools, particularly for diagnostics or complex repairs, are essential. In addition, a well-stocked maintenance kit containing various fluids and parts, including specialized lubricants and filters, is essential for immediate action. Maintaining adequate supplies is crucial for achievementful repairs.

Safe Repair Procedures:

Ensuring safety during roadside repairs is paramount. Following appropriate safety procedures, including proper lifting techniques and the use of safety equipment, like gloves and eye protection, is vital. Understanding the hazards of working with heavy machinery and hazardous materials will keep everyone safe. Knowing the emergency procedures for roadside accidents is a critical part of keeping the crew safe.

Preventative Maintenance Strategies:

Regular Inspections:

Scheduled inspections are key to preventing larger issues. Regular inspections can detect minor problems before they escalate into major mechanical failures. A routine checklist focusing on all critical systems, such as the engine, transmission, brakes, and tires, will make sure you detect issues early. Example: If a crack on a tire is found promptly, you can avoid a catastrophic failure during transit.

Implementing Maintenance Schedules:

Establishing and adhering to a well-defined maintenance schedule is fundamental. Following a pre-determined schedule for each vehicle’s needs will enable proactive intervention before small issues snowball into critical problems. A well-maintained truck is a safer and more reliable truck.

Common Causes of Failures:

Factors affecting reliability:

Understanding the causes of mechanical failures helps establish preventative strategies. Several factors influence the reliability of a truck, including the quality of parts, driving habits, weather conditions, and the frequency of maintenance. For example, inadequate tire pressure can lead to premature tire wear. Analyzing these factors empowers businesses to formulate preventative measures.

Environmental Impact:

Environmental factors significantly impact the lifespan of components in trucking vehicles. Extreme temperatures, harsh weather, and abrasive road surfaces all play a function in increasing wear and tear, and damage to components. Maintaining regular inspections in those kinds of environments will guarantee the safety of your crew.

How can I improve roadside repair efficiency?

To enhance roadside repair efficiency, prepare in advance by ensuring your vehicle maintenance kit is complete and stocked with necessary parts and supplies. Develop standardized repair procedures, training your staff to address common issues quickly and safely. Have readily available access to technical manuals, parts diagrams, and repair guides will expedite the repair process. Using effective communication strategies for roadside assistance services is crucial. Timely notification and accurate information will outcome in swift response times from support crews.

What function does preventative maintenance play in reducing trucking troubles?

Preventative maintenance acts as a critical safeguard against major mechanical failures. It allows early detection and intervention for minor issues before they escalate into more significant problems. Regular maintenance not only minimizes downtime but also preserves the overall condition of the vehicle. Maintaining a consistent schedule of inspections, lubrication, and other routine tasks will significantly reduce the risk of costly repairs and ensure the longevity of the trucking equipment.

In conclusion, mastering trucking troubles is a crucial facet of safe and efficient transportation. By understanding common mechanical failures and implementing proactive roadside repair strategies, trucking businesses can minimize downtime, maintain safety standards, and maximize profitability. This article has offerd a thorough guide to navigating these challenges. For further assistance or specialized advice, consider reaching out to experienced trucking professionals or participating in industry training programs.