selecting the right safety gear for automotive technicians is paramount to a safe and productive work environment. A mishap in a mechanic’s workshop can have severe consequences, from minor injuries to catastrophic accidents, so ensuring proper safety precautions is not optional—it’s essential. Automotive technicians, entrusted with intricate vehicle maintenance and repairs, operate in a dynamic and potentially hazardous environment. This requires specific safety gear to minimize risks and ensure their wellbeing. This article will outline the essential safety gear, delve into its importance, and guide you through selecting the right equipment for your team. We’ll explore various categories of safety gear and present a detailed breakdown of each item’s functionality.

Understanding the Importance of Safety Gear

The Crucial function of PPE in Automotive Repair

Safety gear isn’t just an additional cost; it’s an investment in the health and well-being of automotive technicians, directly affecting their job satisfaction, productivity, and safety. A thorough safety program can prevent injuries and illnesses in the workplace, and that’s something that all automotive repair shops should prioritize. Understanding the specific hazards of an automotive workshop is vital to creating a safe environment.

determineing Common Workplace Hazards

Automotive repair shops present a variety of hazards, including sharp objects, chemical exposure, moving parts, and electrical risks. Ignoring these hazards can lead to serious accidents, so a good understanding of the risks is essential. Protective gear, including gloves, eye protection, and respirators, plays a vital function in mitigating these risks. A systematic approach to hazard identification and risk management is crucial.

Choosing the Right Safety Gear

There’s no one-size-fits-all solution when selecting safety gear. A thorough approach involves understanding the particular hazards present in each facet of the workplace and selecting the appropriate gear. This involves meticulous planning and consideration of individual job tasks.

Related Post : Choosing Durable Tools for Your Fleet Maintenance Needs.

Essential Protective Gear for Automotive Technicians

Eye Protection

Eye protection is crucial for preventing eye injuries caused by flying debris, sparks, or chemical splashes. Safety glasses, face shields, and goggles are essential, with the choice depending on the specific task. Shop around and select eyewear from reputable brands for the optimal protection. Choosing the right eyewear is essential for long-term eye health in the demanding environment of an automotive workshop.

Protective Clothing and Apparel

Protective clothing, such as fire-resistant overalls, long sleeves, and pants, plays a critical function in shielding technicians from abrasions, lacerations, and burns. Consider materials like high-quality fabrics or reinforced stitching to ensure longevity. The attire must also allow for comfort and complimentarydom of movement. Don’t underestimate the importance of ensuring the protective clothing is appropriate for the specific tasks and risks present in the work environment.

Hand Protection

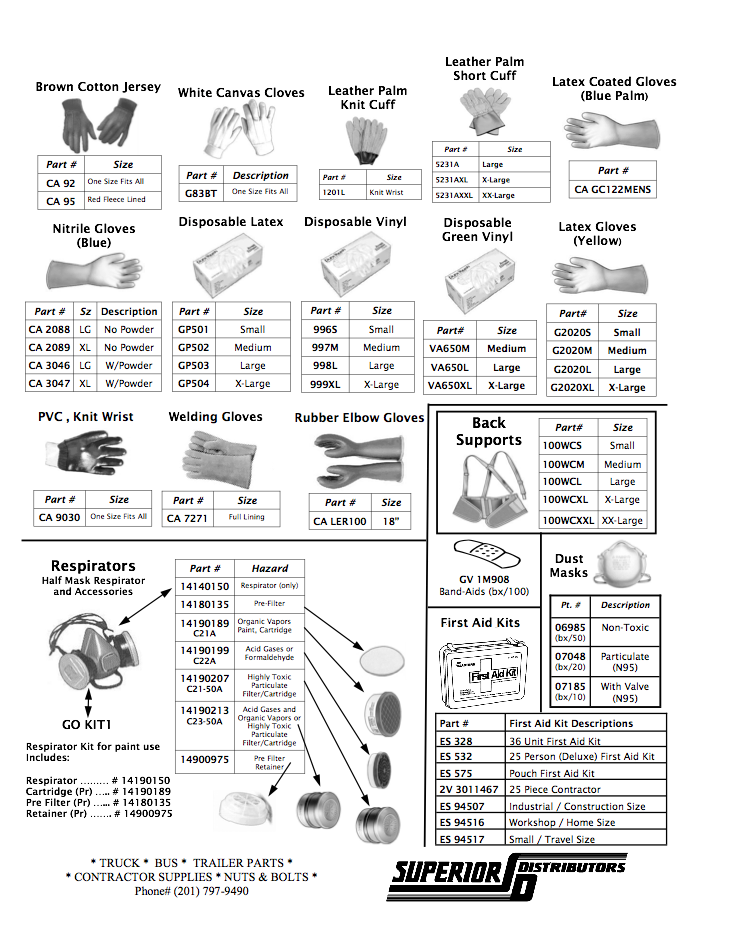

Hand protection is paramount, offering protection from cuts, punctures, and chemical exposure. Using the appropriate gloves (like nitrile or latex) for specific tasks is essential for preventing accidents. Technicians should regularly inspect their work gloves for wear and tear and change them when necessary. Regular maintenance and proper selection are crucial.

thorough Safety Strategies

Implementing Safe Work Practices

This should include enforcing a strict adherence to safety procedures to prevent accidents and injuries from occurring. Safety meetings and training are crucial to reiterate the importance of safety, and to reinforce optimal practices in safe work procedures. This ensures that all staff is aware and understands how to work safely.

Regular Maintenance and Inspection

Regular maintenance and inspection of safety equipment is critical. Make sure you’re using tools in a safe manner. Inspect gloves, safety glasses, and any other safety equipment for wear and tear. Replace worn-out or damaged equipment promptly. Maintain a consistent schedule for inspection.

Emergency Response Plans

Establishing clear and efficient emergency procedures is vital. Ensure that technicians know what to do in case of a workplace incident, whether it be a minor cut or a more serious accident. Regularly reviewing and updating emergency plans ensures efficacy. Emergency plans should be clearly displayed and readily available.

Choosing the Right Safety Gear for Specific Tasks

Working with Fluids and Chemicals

Automotive workshops often involve working with various fluids and chemicals. Using the correct PPE, like chemical-resistant gloves and aprons, is essential to prevent skin and eye irritation and damage. This protects from the many harsh chemicals used in maintenance and repair.

Handling Power Tools

Using appropriate safety glasses, earplugs, or hearing protection, and working gloves when using power tools and machinery are vital. This helps to protect technicians from flying debris and noise-related damage. Regular maintenance and safety checks of power tools are also necessary.

Working with Electrical Systems

Electrical systems present electrical hazards. Using insulated tools and appropriate safety gear is essential to prevent electrical shocks. Regular safety checks of electrical tools, machinery, and equipment are crucial. Use proper electrical safety procedures to prevent electrical shock hazards.

Safety Gear for Specialized Tasks

Working on Elevated Platforms

For tasks involving elevated platforms, fall protection measures are necessary. Technicians need fall protection gear, like harnesses and lanyards, to prevent serious injuries. Working at heights presents particular dangers, so the appropriate measures must be taken.

Working with Compressed Gases

Handling compressed gases requires specific safety gear like pressure-resistant gloves and safety glasses. It’s necessary to properly manage gas pressure to avoid accidents. Working with cylinders and compressed gases requires specific safety awareness and adherence to safe working procedures.

Handling Hazardous Materials

For handling hazardous materials, specialized safety gear and protective equipment must be used in accordance with the material’s safety data sheet (SDS). Knowing how to properly handle and store hazardous materials in a controlled manner is key.

Case Studies on Safety Gear Implementation (optional):

Recommended Safety Gear List (optional):

Additional Resources for Safety Training (optional):

Conclusion to The Top 5 Mistakes To Avoid (optional):

selecting the right safety gear is crucial for automotive technicians ensuring a safe and productive work environment. By prioritizing safety and adhering to optimal practices, technicians can avoid accidents and injuries, ultimately improving their performance and job satisfaction. Investing in top-quality safety gear is not just a precaution but a necessary investment for a long and achievementful career. Check out our recommended gear list for further guidance and explore automotive technician training courses to enhance your skills and knowledge.