Dealing with unexpected auto repairs disrupting your operations can be a real headache, especially if you depend on a vehicle for your business. Imagine your daily route suddenly blocked by a sudden breakdown, or a critical piece of equipment unexpectedly needing repairs. This can create a domino effect impacting schedules, productivity, and ultimately, your bottom line. This article provides a comprehensive guide to tackling unexpected auto repairs and minimizing the disruption to your business operations. We’ll discuss proactive strategies, contingency plans, and effective communication tactics, ensuring you’re prepared and can navigate these challenges with confidence. This article is structured to give you a detailed view of various aspects of handling unexpected auto repairs, from initial assessment to long-term planning.

Proactive Planning for Unexpected Repairs

Implementing a Preventive Maintenance Schedule

Regular maintenance schedules are crucial to preventing unexpected breakdowns. A well-defined schedule should incorporate routine checks, oil changes, tire rotations, and other necessary services. This proactive approach can significantly reduce the likelihood of critical repairs occurring during busy periods or critical projects. For example, a trucking company should schedule regular inspections of its fleet to avoid mechanical failures on the road. Proper maintenance can save a considerable amount of downtime and expenses in the long run. Statistics show that companies with proactive maintenance schedules experience 20-30% less downtime than those without.

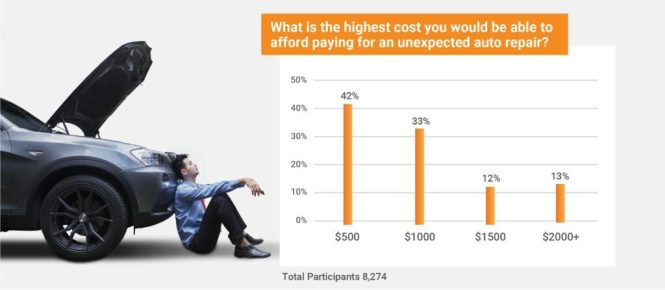

Building a Robust Emergency Fund

While regular maintenance can mitigate risks, unexpected repairs may still occur. Building a contingency fund specifically for these unforeseen circumstances is essential to absorb the cost of unexpected repairs without impacting other critical business operations. This fund will allow you to tackle repairs promptly without financial strain. A trucking company, for example, might allocate a portion of its monthly revenue to a repair fund. This foresight can provide peace of mind during unplanned repair events and prevent the need for short-term loans or high-interest financing.

Assessing the Situation and Determining the Next Steps

Immediate Assessment of Damage and Costs

When an unexpected repair arises, assess the extent of the damage to determine the potential costs involved. Is it a simple fix or a major overhaul? Obtain quotes from multiple repair shops to ensure competitive pricing and avoid overpaying. This will allow you to have several options and alternatives in case a price seems too high. A detailed assessment of the situation is vital for planning. For example, if your delivery truck has mechanical issues, get an estimate of the repair cost and schedule it as soon as possible. Also, try to estimate the expected downtime for the repairs to minimize the impact on your operations.

Engaging with Repair Professionals

Contact reputable and reliable auto repair professionals to expedite the repair process. Choose a workshop that specializes in the type of vehicle requiring repairs. A trucking company, for example, might use a specific mechanic specializing in heavy-duty trucks to ensure proper and specialized knowledge of these types of vehicles. Communicate your needs clearly to ensure they understand the urgency and potential implications on your operations.

Related Post : Ignoring Routine Vehicle Upkeep Costing Your Business Money?

Minimizing Downtime and Maintaining Operations

Utilizing Backup Vehicles or Services

Having alternative transportation options in place is a key element of business continuity. If possible, maintain a backup vehicle or a network of trusted service providers who can step in during unexpected repairs. A small business, for instance, might arrange with another delivery company to cover deliveries if their primary vehicle is out of service. Consider this as an option for maintaining momentum and continuity during the repairs.

Adapting Schedules and Operations

If possible, modify schedules and operations to minimize the impact of the repair. For example, if a delivery truck is out of service, redistribute deliveries among available vehicles, use alternate routes to avoid delays, and contact customers beforehand to alert them about schedule changes. Proactively adjusting to these changes is key to maintaining operations during unforeseen circumstances. Adapting schedules and operations also includes the implementation of alternative plans, such as prioritizing essential deliveries during this period.

Communication is Key for Effective Solutions

Open Communication with Your Team

Clear and effective communication is crucial to ensuring minimal disruption to your business operations. Inform your team about the situation promptly and clearly explain how the repair will affect their tasks or responsibilities. For example, in a logistics company, keeping the drivers, supervisors, and managers informed of the truck’s unavailability is essential to maintaining a smooth and predictable operation. This is important to avoid confusion or delays.

Transparent Communication with Customers

Maintain open communication with your clients, informing them about any delays that may result from unexpected repairs. Providing updates and estimates for the return to service can help manage client expectations. It is important to explain any modifications to the delivery schedule to avoid potential conflicts. A good example is sending email or text notifications to customers about the delay and an estimated time of arrival.

Contingency Planning and Long-Term Solutions

Creating a Contingency Plan

A well-defined contingency plan can outline steps to take in the event of unexpected auto repairs, minimizing potential business disruptions. This can include alternative transportation arrangements, rescheduling client appointments, and notifying necessary personnel. For example, a business owner should have an emergency contact list, along with a designated person responsible for coordinating and implementing the plan. This proactive measure gives you more control over the unexpected. This plan should be regularly reviewed and updated.

Investing in Preventative Maintenance

Instead of solely reacting to unexpected repairs, invest in proactive maintenance strategies. This can include routine inspections, early repairs for potential problems, and exploring new technologies. A trucking company, for example, can benefit from preventative maintenance to prevent costly repairs down the road. Investing in preventive maintenance reduces downtime and overall maintenance costs.

Case Studies and Examples

Example of a Logistics Company

A logistics company experienced a sudden breakdown of its primary delivery truck, disrupting critical deliveries. They had a backup vehicle, allowing them to maintain a certain level of service, and promptly communicated the delay to their customers. They also utilized alternative routes to bypass the road closures caused by the repair. This effectively minimized the impact of the unforeseen repair.

Example of a Transportation Company

A transportation company proactively invested in a well-defined preventive maintenance schedule for its fleet. This minimized the likelihood of critical failures during peak seasons. They also established a contingency fund for unexpected repairs. This helped them absorb unexpected repair costs without impacting other aspects of their business.

Importance of Data-Driven Decisions

Data analysis plays a critical role in evaluating the effectiveness of your strategies for dealing with unexpected repairs. Tracking metrics like repair frequency, downtime costs, and customer satisfaction provides insights into potential areas of improvement.

Additional Tips for Business Continuity

Regular Safety Checks

Ensure that all vehicles are routinely inspected for safety before use. This can minimize potential accidents or incidents during operations.

Training for Staff

Provide training to staff on how to handle emergency situations, including those related to unexpected vehicle repairs, ensuring they are prepared to act swiftly and effectively.

In conclusion, unexpected auto repairs can severely disrupt business operations. By proactively planning for these events, implementing a robust contingency plan, and fostering strong communication with your team and customers, you can minimize the negative impacts and maintain a positive outlook. Remember to always prioritize safety and seek expert advice when dealing with any mechanical issues. Now go forth and conquer those unexpected repairs! For more tailored support, consult with a specialist or explore our resources at [website address].