Tracking maintenance schedules for your bike fleet is essential for smooth operations. A well-maintained fleet ensures consistent service delivery, reduces unexpected downtime, and maximizes the lifespan of your vehicles. This article will delve into the crucial elements of an effective maintenance schedule, identifying common pain points and providing actionable solutions. We’ll explore how to establish a robust schedule, track progress, and ultimately minimize unexpected costs and downtime. The structure will cover the core elements from defining your schedule to tracking and reporting.

Understanding the Importance of Scheduled Bike Maintenance

The Foundation of a Smooth-Running Fleet

Effective maintenance isn’t just about fixing problems; it’s about preventing them. A well-defined schedule helps identify potential issues early on, allowing you to address them before they escalate into costly repairs. This proactive approach is crucial for maintaining peak performance throughout your bike fleet. Without a schedule, you risk increased maintenance costs, damage to equipment, and ultimately, the quality of service offered. By proactively planning and executing maintenance tasks, you are minimizing your operational costs and ensuring that your fleet is always ready for service.

Identifying Potential Issues Before They Happen

A proper maintenance schedule allows you to detect small problems that can easily be fixed early on, ultimately reducing the chance of significant and costly damage down the line. Identifying these small problems often requires a skilled eye and a deep understanding of the machinery. Preventive measures are key to preventing significant issues that could lead to lengthy delays in service. A well-structured schedule facilitates regular inspections, which allows you to detect wear and tear before it compromises the integrity of your bikes.

Establishing a Comprehensive Maintenance Schedule

Defining Key Tasks and Frequencies

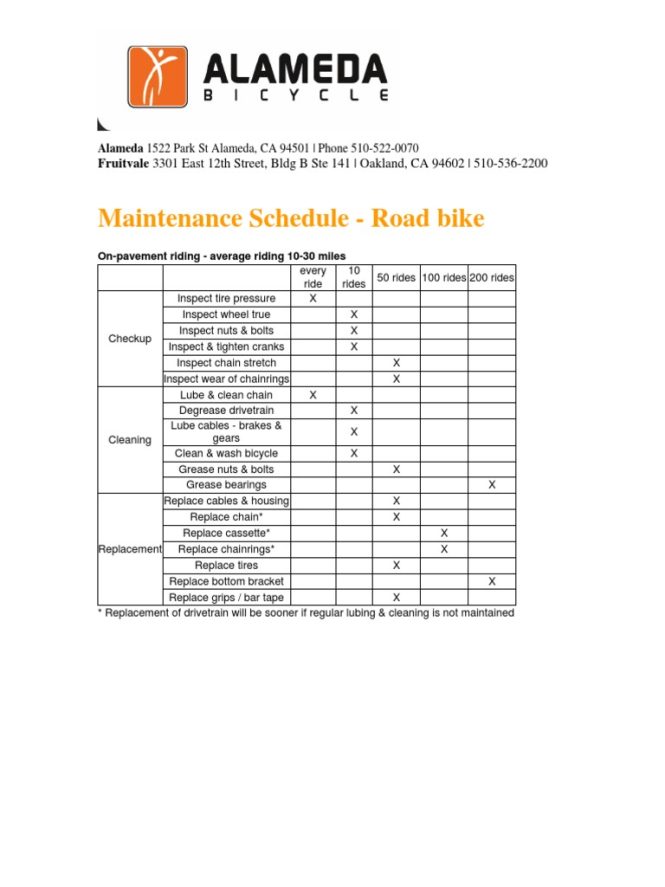

Create a detailed schedule that outlines specific tasks, like lubricating chains, checking tire pressure, and inspecting brakes. Establish a frequency for each task; some tasks might need to be performed daily, while others can be scheduled weekly, monthly, or quarterly, depending on the use and type of bike.

Utilizing Technology to Streamline the Process

Employing digital tools can simplify the process of tracking maintenance tasks. Digital tools can help you create a more robust schedule that is easily adaptable and scalable as your fleet grows. These tools also provide a structured way to document the work completed on each bike, providing insight into its history and overall lifespan.

Related Post : Ensuring Motorcycle Rider Safety for Your Business Operations.

Prioritizing Safety and Compliance

Ensure that all maintenance procedures adhere to safety guidelines and relevant regulations. Documenting every maintenance event keeps your business organized and legally compliant. Always adhere to established safety guidelines for both your team and clients to ensure everyone is working as safely as possible.

Implementing and Tracking Your Maintenance Schedule

Setting Up a Centralized Database

A centralized database is crucial for tracking and organizing maintenance tasks, parts, and relevant information for each bike in your fleet. By centralizing the information, you improve accessibility and efficiency in case of any emergency or need for rapid access.

Utilizing Reporting Tools

Use data-driven reporting tools to monitor the performance of your maintenance schedule and identify any trends or potential problems. Data from these tools can help to ensure that your schedules are aligned with your fleet’s needs and ensure that maintenance is being carried out properly.

Addressing Common Challenges

Dealing with Unexpected Downtime

Having a proactive maintenance schedule can help mitigate unexpected downtime. Unexpected maintenance events are a common issue that often impacts the operational efficiency of a fleet. Having a well-defined maintenance schedule will assist in the planning of resources and allow for adequate staffing and spare parts inventory.

Managing Maintenance Costs

Tracking maintenance costs is critical for optimizing budget allocation and identifying areas for improvement. Data-driven analysis of maintenance costs can reveal patterns and areas where expenses can be reduced.

Optimizing Performance and Efficiency

Maximizing Fleet Life Span

Proper maintenance significantly extends the lifespan of your bikes, minimizing replacements and associated costs. This involves not only planned maintenance but also the quick resolution of any malfunctions that may occur.

Ensuring Consistent Quality of Service

Maintain a consistent high level of service by ensuring that your fleet is always ready to operate. This will improve client satisfaction and ensure higher operational efficiency.

Using Fleet Management Software

By utilizing modern software, you can easily manage all aspects of your fleet, making tracking maintenance schedules a breeze. This will help to streamline your operations and provide a clear view into the health and status of your fleet.

In conclusion, effectively tracking maintenance schedules for your bike fleet is crucial for optimizing performance, minimizing downtime, and maximizing ROI. By implementing a robust system, you can proactively address potential issues, ensuring the continued smooth operation of your fleet. Consider partnering with a fleet management solution provider if you need a more sophisticated system. This will save you time, and effort, and ultimately generate significant savings.