Monitoring tire pressure for better mileage in business cars is essential for maximizing fuel efficiency and reducing maintenance costs. Imagine a fleet of vehicles consistently achieving peak performance, with minimal downtime and maximized uptime. This is achievable through a proactive approach to tire pressure management. Proper tire inflation directly impacts a vehicle’s fuel economy, tire lifespan, and overall performance, all of which translate into significant savings for businesses. This article will delve into the crucial aspects of monitoring tire pressure, highlighting the issues, potential solutions, and the long-term benefits for your business fleet. We’ll explore the technical aspects of tire pressure, how to monitor it effectively, and present practical strategies to incorporate monitoring into your vehicle maintenance routines.

The Impact of Tire Pressure on Fuel Efficiency

Understanding the Correlation

Tire pressure is intrinsically linked to fuel efficiency. Under-inflated tires increase rolling resistance, causing the vehicle to consume more fuel to overcome this resistance. Over-inflated tires, conversely, can also negatively impact fuel efficiency, although to a lesser degree. Studies have shown that maintaining the proper tire pressure can result in significant fuel savings, potentially ranging from 1-3% depending on various factors, which can translate to substantial cost reductions over the lifetime of a fleet of vehicles.

Practical Examples

Consider a business with a fleet of 100 vehicles. If each vehicle experiences a 2% increase in fuel consumption due to improper tire pressure, the cumulative increase in fuel costs annually could be substantial. Conversely, maintaining proper tire pressure could lead to considerable savings, making it an economically sound practice for fleets.

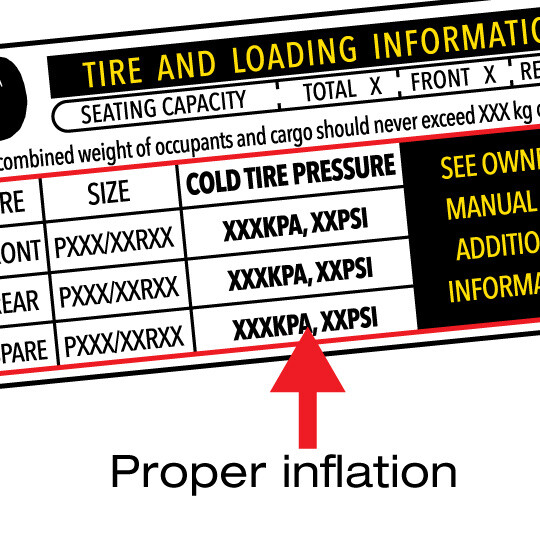

The Role of Proper Inflation

Proper tire inflation is crucial for optimal performance. It ensures the tire distributes the load evenly, preventing uneven wear and tear on the tread. This optimized distribution enhances the tire’s contact with the road surface and reduces the risk of damage from sharp objects or potholes.

Implementing a Tire Pressure Monitoring System

Choosing the Right Approach

Implementing a tire pressure monitoring system is a vital step toward achieving optimal performance and maximizing the lifespan of your tires. There are various approaches to consider, ranging from basic manual checks to sophisticated automated systems. Choosing the right approach depends on the size of your fleet, your budget, and the level of precision required.

Manual vs. Automated Systems

Manual monitoring involves regular checks with a pressure gauge. This method works well for smaller fleets, but it requires consistent effort and attention to detail. Automated systems, on the other hand, are more efficient for larger fleets. They often utilize sensors and alerts to provide real-time data on tire pressure, reducing the risk of critical tire issues.

Benefits of Automation

Automated systems offer several benefits, including enhanced safety and improved operational efficiency. Real-time data analysis allows for prompt intervention in case of a critical tire pressure issue, reducing the risk of accidents. Automated systems also eliminate human error, enhancing consistency and accuracy in tire pressure management.

Maintaining Consistent Tire Pressure

Regular Checks and Inspections

Consistent tire pressure checks are essential to ensure optimal performance. Regular inspections, performed by trained personnel at scheduled intervals, can help detect issues and ensure the proactive maintenance of tire pressure.

Developing a Maintenance Schedule

Developing a clear maintenance schedule is crucial for effective tire pressure management. This schedule should incorporate the specific requirements of different vehicles within the fleet. Consider factors like tire type, vehicle weight, and driving conditions.

Best Practices for Vehicle Inspections

Implementing best practices for vehicle inspections is vital for proper tire pressure monitoring. This includes using calibrated gauges, checking pressure for all tires, noting any discrepancies, and taking necessary corrective actions. For example, in situations where air pressure is consistently below the recommended limit, an underlying issue, such as slow leakage, needs to be identified and addressed promptly. This preventive approach prevents more serious problems and enhances the longevity of tires.

The Cost Savings of Tire Pressure Monitoring

Reducing Fuel Consumption

As mentioned earlier, maintaining proper tire pressure directly contributes to fuel savings. By ensuring consistent tire inflation, businesses can significantly reduce fuel consumption, leading to substantial cost savings over time.

Extending Tire Lifespan

Optimizing tire pressure leads to more even tire wear, significantly extending tire lifespan. This reduction in replacement frequency translates into considerable cost savings on tire replacements.

Minimizing Maintenance Costs

Proactive monitoring of tire pressure can minimize costly maintenance issues. By preventing uneven wear and tear and promptly addressing pressure problems, businesses can reduce the need for expensive repairs.

Related Post : Choosing Fuel-Efficient Vehicles for Your Business Needs.

Best Practices for Monitoring Tire Pressure in Business Cars

Utilize Technology

Consider implementing tire pressure monitoring systems for fleet management. These technologies help to monitor tire pressure on multiple vehicles simultaneously. Advanced systems automatically adjust tire pressure based on real-time conditions, optimizing efficiency.

Establish Training Programs

Implement training programs to educate your fleet drivers on the importance of checking tire pressure regularly and maintaining recommended pressure levels. Ensure your maintenance personnel is properly trained on diagnosing and addressing tire pressure-related issues.

Regular Audits

Conduct regular audits of the implemented monitoring systems to identify and address any gaps or areas for improvement. This approach keeps your tire pressure monitoring system efficient and ensures ongoing compliance with safety guidelines.

Case Studies of Successful Tire Pressure Management

Example 1

A company with a large trucking fleet reduced its fuel consumption by 3% after implementing a tire pressure monitoring system and training program for their drivers. This saving directly translated to significant cost savings on fuel over a year.

Example 2

Another fleet saw a 15% reduction in tire replacements after implementing a tire pressure monitoring system. This reduction in tire replacement frequency directly translated to significant cost savings on tire replacements.

Real World Evidence

These case studies exemplify the real-world benefits of proactive tire pressure monitoring. The impact on fuel efficiency, tire lifespan, and overall operational costs can be substantial, making it a vital aspect of fleet management for any business operating vehicles.

Measuring the Return on Investment (ROI) of Monitoring Tire Pressure

Addressing Common Tire Pressure Problems

Conclusion of Tire Pressure Monitoring Systems in Business Car Maintenance

In conclusion, monitoring tire pressure consistently is crucial for maximizing the mileage of business cars. By understanding the importance of proper tire inflation, businesses can significantly reduce fuel consumption, extend tire lifespan, and optimize overall vehicle performance. Implementing a proactive monitoring system, whether it’s through regular checks or automated technology, is a worthwhile investment in the long run. Schedule a free consultation today to learn how we can help your business achieve better fuel efficiency and reduced maintenance costs through tire pressure monitoring.