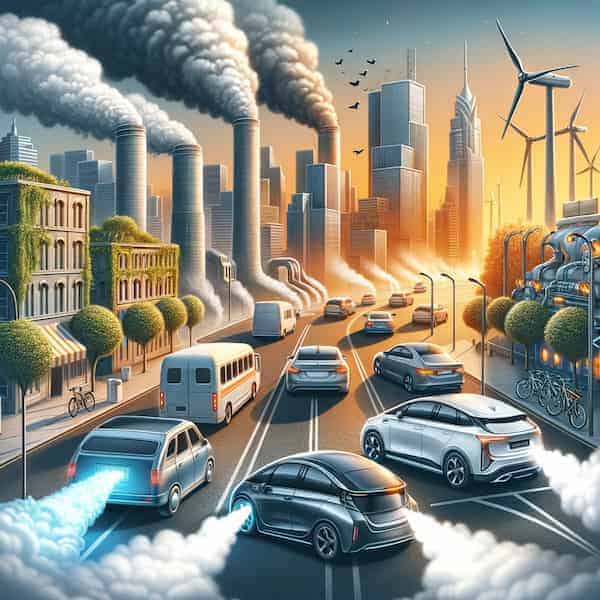

The environmental impact of electric car production is a complex issue with significant implications for our planet’s future. While electric vehicles (EVs) offer a promising alternative to traditional internal combustion engine vehicles, the manufacturing process isn’t without its environmental trade-offs. This article delves into the intricate environmental footprint associated with electric car production, exploring the challenges and opportunities for more sustainable practices. We will examine the lifecycle of an EV, from raw material sourcing to battery production, vehicle assembly, and eventual disposal, to assess the total environmental cost. By understanding these nuances, we can evaluate the true sustainability of EVs and identify strategies for enhancing their environmental profile.

Raw Material Sourcing and its Environmental Impact

Mining Practices and Biodiversity

The production of electric vehicles relies heavily on the extraction of raw materials, including lithium, cobalt, nickel, and rare earth elements. Often located in politically unstable or environmentally vulnerable regions, the mining of these materials can severely damage local ecosystems. Poor mining practices, lacking proper environmental regulations or oversight, frequently result in deforestation, water contamination, and habitat destruction. For instance, a study from the World Wildlife Fund revealed significant biodiversity loss in regions with high-volume mining activities, highlighting the dire consequences of irresponsible resource extraction. The extraction of raw materials required for the production of electric vehicle batteries often involves practices that cause considerable damage and pollution to the local environment.

Alternative Sourcing Solutions

Fortunately, there are alternative solutions to tackle this challenge. Investing in sustainable sourcing practices, including the promotion of recycled materials or the exploration of alternative sources for critical minerals, can mitigate the environmental impact significantly. This involves collaborating with mining companies and local communities to implement environmentally conscious mining techniques. Stricter regulations are needed to ensure the responsible and ethical sourcing of raw materials for vehicle components, thus helping to prevent further environmental degradation and supporting the creation of a greener supply chain. Using recycled materials in the manufacturing process and exploring new alternative materials can also reduce the environmental burden considerably.

Battery Production: A Key Environmental Concern

The Environmental Footprint of Battery Manufacturing

Battery production, particularly for lithium-ion batteries, is a significant contributor to the environmental footprint of electric cars. The process requires substantial energy input, often from fossil fuel sources, generating harmful emissions and contributing to greenhouse gas (GHG) emissions. Further complicating the issue is the reliance on toxic chemicals and materials used in the battery manufacturing process, which can pose risks to human health and the environment if not handled properly. These issues can cause lasting damage to the environment, especially when not managed properly, and raise concerns about the potential for long-term environmental impacts associated with the production process.

Sustainable Battery Production Practices

To reduce the environmental impacts of battery production, increased investment in sustainable practices is essential. Companies should prioritize the use of renewable energy sources in manufacturing processes to minimize the reliance on fossil fuels. Furthermore, the implementation of closed-loop recycling systems for battery materials is vital to reduce waste and recover valuable resources. Developing new battery chemistries with reduced environmental impacts and utilizing recycled materials is another critical strategy for minimizing the total environmental footprint. Companies are already starting to explore these innovative approaches, which include designing batteries with longer lifespans, improving the efficiency of materials utilization, and implementing strict quality control measures to avoid harmful emissions during production.

Related Post : Understanding New EV Regulations Impacting Your Business Fleet.

Vehicle Assembly and Transportation

Manufacturing Processes and Emissions

The assembly of electric vehicles also contributes to the overall environmental impact. The transportation of components from various suppliers to the assembly plant generates significant greenhouse gas emissions. Moreover, the use of energy during the manufacturing processes, including welding, painting, and final assembly, also generates emissions. Evaluating the transportation impacts and optimizing logistics are crucial aspects of minimizing this phase of the production lifecycle.

Optimizing Logistics and Transportation

To lessen the impact of these transportation and manufacturing processes, optimizing supply chains and promoting the use of sustainable transportation methods are essential. Implementing strategies such as utilizing electric vehicles for internal transportation within the manufacturing facilities and promoting the use of recycled or sustainable materials during the vehicle assembly process can significantly reduce greenhouse gas emissions. Furthermore, working with suppliers who prioritize ethical and sustainable practices can further contribute to responsible production.

Vehicle Disposal and End-of-Life Management

Battery Recycling and Material Recovery

The end-of-life management of electric vehicles poses unique challenges compared to traditional vehicles. The batteries, in particular, contain valuable materials, making recycling and material recovery crucial. However, proper battery recycling facilities are not widely available, leading to potential environmental risks if not managed properly. This lack of adequate infrastructure and expertise in battery recycling significantly hinders the overall sustainability of electric vehicle production.

Developing Sustainable Recycling Infrastructure

The development of robust recycling infrastructure, along with the creation of well-regulated recycling markets for EV batteries, is critical for sustainable end-of-life management. Government policies and regulations that promote recycling of EV batteries, and financial incentives for establishing battery recycling facilities, are vital for ensuring the responsible handling of electric car components at their end-of-life.

The Role of Consumers and Policy Makers

Consumer Awareness and Responsible Purchasing

Consumer awareness and responsible purchasing choices play a significant role in influencing the sustainability of electric car production. Consumers should prioritize manufacturers that are committed to ethical and sustainable practices, prioritizing companies who have a robust track record of environmental responsibility. This awareness can drive businesses to implement sustainable practices, further reducing the negative effects on the environment. Consumers can support sustainable practices by researching the manufacturing process of the vehicles they choose and actively participating in the market’s demand for environmentally friendly options.

Policy Interventions and Incentives

Policy interventions and incentives can significantly affect the sustainability of electric car production. Governments can incentivize the development and adoption of sustainable technologies, including sustainable sourcing, battery recycling, and environmentally conscious vehicle assembly. Regulations that promote the use of recycled materials, alongside promoting ethical sourcing and environmental consciousness, can further encourage eco-friendly practices and minimize the environmental impact of electric car production.

Understanding the environmental impact of electric car production is crucial for a sustainable future. This article highlighted the complexities involved, from raw material extraction to battery manufacturing and vehicle disposal. Moving forward, greater transparency, responsible sourcing, and improved recycling infrastructure are essential. Consumers can play a role by supporting manufacturers committed to eco-friendly practices. Governments, too, have a vital role to play in setting standards and incentives for sustainable production. By collectively addressing these challenges, we can strive toward a future where electric vehicles contribute to a healthier planet.